RovR

RoLLR 45Q Cooler

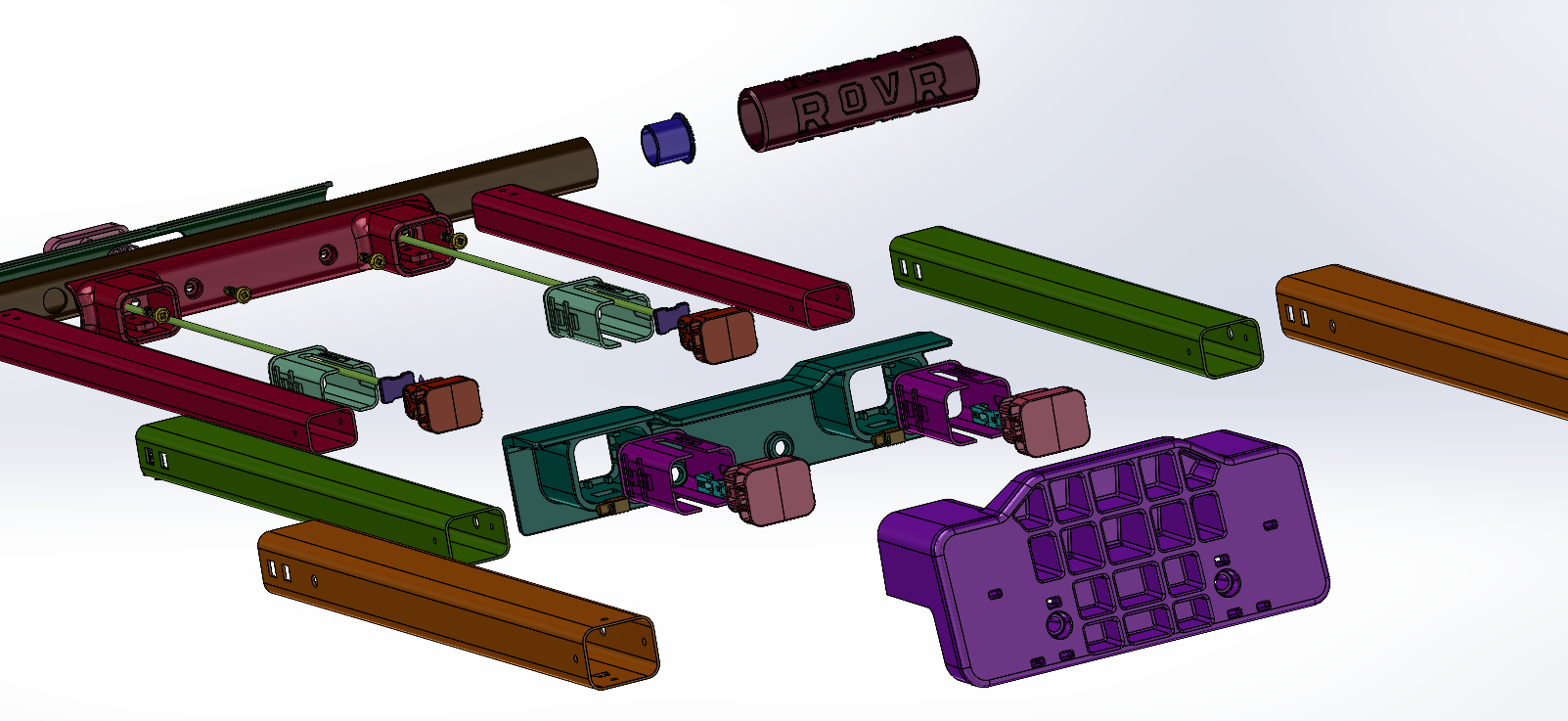

Dvelop Design helped take an already great product, RoVR’s first generation of rotomolded coolers, and helped convert them to injection molding for efficiency, in addition to improved elements like a more durable handle, easy to use cam over latches, a dry bin and more.

As ROVR transitioned from rotomolded coolers to more advanced injection mold models I was able to insure an optimum outcome drawing from a wealth of experience with over 20 years of background in injection molding.

Iterative Improvements All Around

Cam Latches

Switching from the legacy rubber pull over latches to more sophisticated compound latches meant a much better experience when opening and closing the cooler. This was accomplished without changing the cooler design, meaning perfect backwards compatibility.

Improved Handle Design

A combination of quality sourcing and design improvements resulted in a vastly improved user experience.

Sourcing Validation and Communication

Dvelop design isn’t just design and engineering. Through vast amounts of experience with factories throughout APAC, I can find suppliers, vet their capabilities, negotiate pricing, and customize solutions to fit customers needs.

For ROVR Products, Dvelop design looked for suppliers all across the APAC region for the highest quality and most cost effective JDM partners.

Handle Sourcing for RovR

A vastly improved design accomplished by finding an improved supply chain, and working closely through that supplier to make a perfect custom solution for RovR Coolers. Dvelop Design helped in all these key areas:

Supplier Sourcing and Vetting.

Price negotiations and competitive quoting.

JDM model, working with the supplier to get the perfect design.

Quality assurance and testing validation.

Want to see what I could do for you?

Contact me to see how I can help you with strategic sourcing and product development on your project.